Solar Power Plant Inspection Service

Solar Power Plant Inspection Service

Our inspection performed so far

Inspected power plants: 319

detail|

< 2MW |

180 sites |

|

2MW-10MW |

38 sites |

|

10MW-50MW |

73 sites |

|

50MW-100MW |

15 sites |

|

> 100MW |

13 sites |

*As of December 31, 2023. Some power plants have been inspected several times.

Service Outline

Provides inspection services on site at the same level as solar panel manufacturers

We provide various performance/safety tests including insulation resistance measurement, ground resistance measurement as well as string I-V inspection, EL inspection, and IR inspection using thermography.

We provide services of pre-operation voluntary test and pre-operation self check, mandated by revision of FIT scheme in 2023 for solar plants of 10kW – 2,000kW.

Through partnership with cooperating companies, we also cover integrated O&M services including regular safety checks performed every month or year.

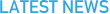

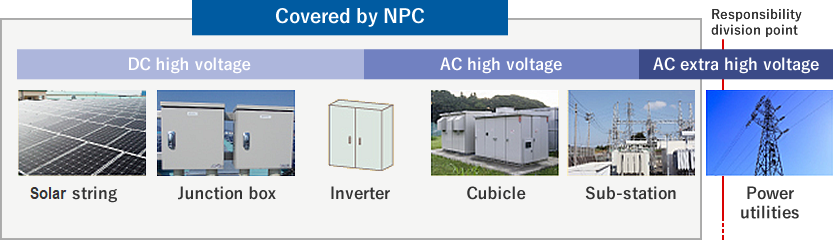

Total services covering DC to AC

Completion testPre-operation voluntary inspection Pre-opereation self check |

Performance/SafetyI-V characteristic inspection Voc measurement Visual check Insulation resistance check Ground fault resistance test EL inspection IR inspection |

SafetyMonthly check Regular check Annual check |

Introducing our integrated inspections/maintenance service of solar power plants

(5 min. 51 sec. with sound)

Advantages of NPC

- Providing our unique analysis ability and detailed reports

- Superb on-site flexibility based on a number of inspection performances

- Good cost performance through nationwide network

- Proposing a wide variety of inspections covering DC to AC

Main inspections

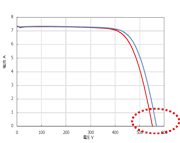

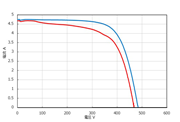

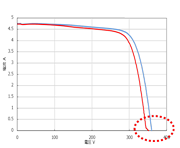

I-V inspectionUse of “Rakit,” our multi-functional high-speed I-V measurement system, shortens inspection time and saves power loss to the minimum level. Highly accurate analysis results will be automatically provided through the data conversion under STC (temperature: 25℃, irradiance: 1,000W/m²). |

|

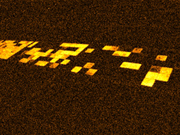

On-site EL/PL inspectionUse of “EPTiF,” our original EL/PL inspection machine enables us to perform EL/PL inspections during daytime without removing panels. It provides detailed inspection in an easy and safe manner, identifying all the defects and their causes from micro-cracks to disconnection and PID. |

|

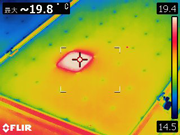

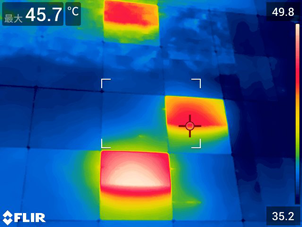

IR inspection (by thermography)Temperature measurement by IR using the high-resolution thermographic camera (E75) by FLIR identifies faulty panels with hot spots, etc. Efficient IR inspection using a drone is also available. |

|

Other inspectionsUsing “DCFT,” DC safety inspection device for solar panels, we check ground fault resistance, break in electric path, bypass diode disconnection, etc. and identifies faulty panels in a short time. We also provide visual check required at pre-operation voluntary inspection, insulation resistance measurement, ground resistance measurement, dielectric strength test. Efficient barcode reading is also available, utilizing our experience. |

|

NPC Original Maintenance Service

According to our customer's needs, we provide various inspection/maintenance services.

Case study

Spot inspection■Capacity : approx. 4MW / 3 years after installation |

|

Completion inspection (Pre-operation voluntary inspection)■Capacity:approx. 20MW |

|

Completion inspection (Pre-operation voluntary inspection)■Capacity:over 50MW |

|

Regular maintenance■Capacity: 100kW rooftop system |

|

Maintenance Service Flow

- Inquiry

- Obtaining power plant information

(spec of panels and junction boxes, connection block diagram, panel distribution drawing, etc.) - Proposal of estimates

- On-site inspection

- Providing analysis report

Case Study

Matsuyama Foundation for Culture and Sports Promotion

Outline of the solar system

- Start of operation: 2001

- Location: Matsuyama Outdoor Activity Center, Matsuyama city, Ehime Prefecture

- Number of panels: more than 400 panels deployed on the ground and rooftop, respectively

- Generation capacity: 100kW

Purpose of inspection

We inspected the system to confirm if it was operating in a sound condition after more than 15 years (at the time of the inspection) of operation, both in the view of safety and performance. If any problems were found, we were to identify the causes.

Contents of inspection

We performed visual inspection, Voc measurement, disconnection test, ground fault resistance test, I-V inspection, and IR inspection using thermography camera in one day.

Result of inspections

We found panels with melting backsheets, disconnection and broken glass, hotspots, and electrical insulation failure. We issued a report stating each problem and the considered causes, and secured safety by disconnecting the panel strings with insulation failure. We also replaced the disconnected panels with new ones.

|

|

|

|

The panels installed on the rooftop were estimated to have caused high resistance and open bypass circuit, considering the significantly lower FF compared with those on the ground. As they were installed on the rooftop, where dissipation of excess heat was limited, we recommended the customer to remove the panels to avoid a fire risk. As a result, the whole rooftop system was moved away. As to the ground-mounted system, all the defective panels were exchanged to good-quality panels and secured safety. Since then, the system has continued to generate power without any problem. The customer asked us to perform regular inspections and maintains the soundness and safety of the system.

Customer's voice - reviewing our inspections

"When we found abnormal operation of the rooftop solar system, we asked NPC for inspections of our solar systems. As a result, several defects including damage by heat were found. To secure safety, we removed all the panels installed on the rooftop.

Since NPC provided us with appropriate proposals from a series of inspections to the actions in the future, we were able to solve the problem quickly. We thrive to operate the Outdoor Center safely and comfortably by performing safety check of the ground-mounted panels at the regular inspections."

Examples of Solar Power Plants Inspected So Far

Company J

Site: Yamaguchi Pref. |

Company J

Site: Yamaguchi Pref. |

Kikuno Co., Ltd.

Site: Ehime Pref. |

Company J

Site: Yamaguchi Pref. |

Chudenko

Site: Hiroshima Pref. |

Kishiro Co., Ltd.

Site: Ehime Pref. |

Lixil

Site: Kumamoto Pref. |

Matsuyama Kanko Golf

Site: Ehime Pref. |

Company A

Site: Shiga Pref. |

Mirait Technologies

Site: Chiba Pref. |

JFE Technos

Site: Tochigi Pref. |

JXTG Energy

Site: Kagawa Pref. |

JXTG Energy

Site: Ehime Pref. |

JXTG Energy

Site: Ehime Pref. |

JXTG Energy

Site: Ibaraki Pref. |

JXTG Energy

Site: Akita Pref. |

Environmental Business

Solar Panel Reuse/Recycling

PV Panel Inspection Machine and Others

Solar Power Plant Inspection Service