Automated Solar Panel Disassembly Equipment/Line

We provide solar panel disassembly equipment both in a fully-automated line and as a stand-alone machine.

Product lineups

Automated Solar Panel Disassembly Equipment/Line

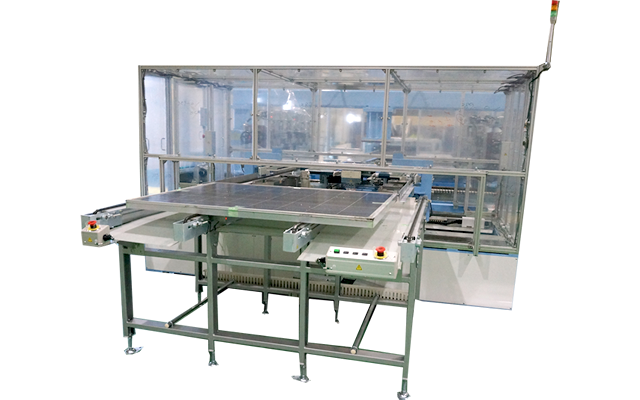

Equipped with "separation method using a heated blade" (patented technology). Automatically separates glass from other materials.

Stand-alone equipments available according to customers' needs. (Frame Separator, J-Box Separator, and Glass Separator)

|

Semi-automated Frame & J-Box Separator

Automatically separates 4 frames and a J-Box. Can be loaded on a truck for on-site operation, which leads to a reduction of transportation cost.

|

Automated Solar Panel Disassembly Equipment/Line

Features

*8 hours per day, 300 days per year |

|

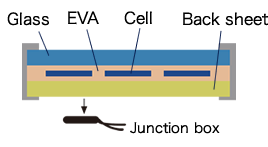

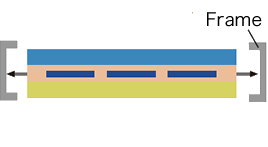

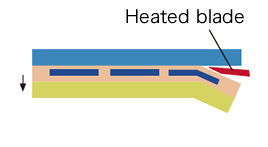

What is the separation method using a heated blade?

|

In this method, a blade heated to 300℃ melts EVA layer to separate glass from other materials. |

Specifications

| Line size (W) x (H) | 16.7 x 2.0 m |

|---|---|

|

Applicable panel |

Solar panel with back sheet |

|

External dimension of panel |

Min: 800 x 800 mm Max: 1,090 x 2,100 mm |

| Glass thickness | 2.8 - 4.0 mm |

| Frame thickness | 40 - 60 mm |

| J-Box position | Short side: center of a panel Long side: 40 - 150 mm from edge of a panel |

| Process time | Approx. 60 seconds (for 6 x 10 panels) *It may change depending on the panel conditions. |

| Interface | Touch screen (password, trouble/alarm management, counter functions) |

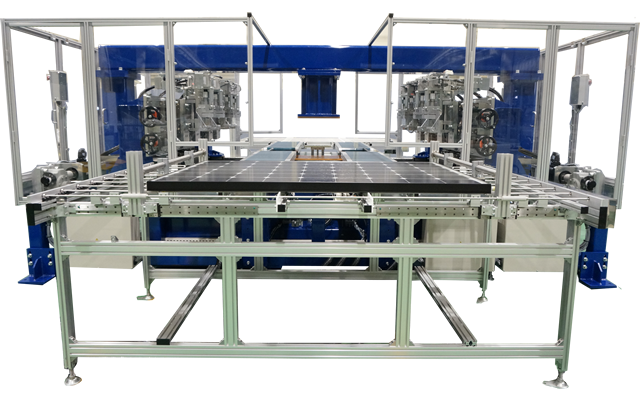

Semi-automated Frame & J-Box Separator

We provide Semi-automated Frame & J-Box Separator, which separates 4 frames and a J-Box automatically at a time, in as little as 40 seconds. Loaded on a truck with a generator, it will function as a mobile separator to disassemble panels on site.

Features

|

|

Specifications

| Size (W) x (H) x (D) |

2,900 x 1,600 x 1,700 mm |

|---|---|

|

Applicable panel |

Solar panel with back sheet, Double glass panel |

|

External dimension of panel |

800 x 1,200 mm, 1,000 x 2,000 mm |

| Glass thickness |

2.8 - 4.0 mm |

| Frame thickness |

30 - 60 mm |

| J-Box position | Short side: center of a panel Long side: within 150 mm from edge of a panel |

| Process time |

Approx. 40 seconds after setting *It may change depending on the panel conditions. |

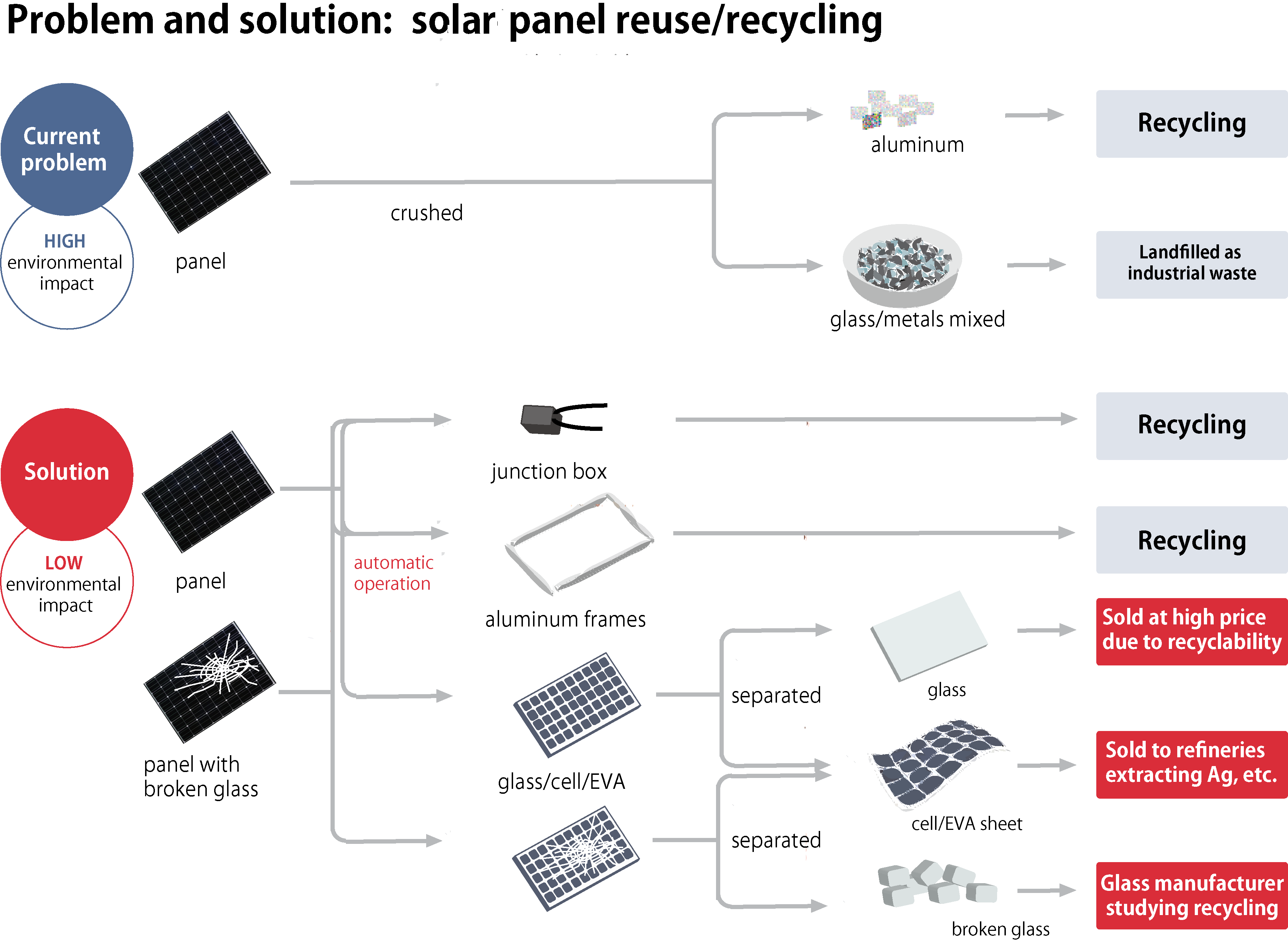

Background of development of disassembly line

While installation of solar systems has increased worldwide, it is expected that a massive amount of end-of-life panels will be discarded in the future. The recycling scheme of solar panels, however, is yet to be established. Currently, in many countries including Japan, solar panels are just shredded as general industrial wastes, leaving valuables such as silver and copper uncollected. Solar panels should be treated carefully as they may cause electric shock. Awareness of such risk, however, is still very low.

We started to develop solar panel recycling technology in 2013, to solve this problem.

Recycling glass, weight of which takes around 70 to 80 percent of a panel, is impossible if there are metals. After crushing a panel as an industrial waste, it is extremely difficult to separate glass from metals.

Therefore, we have developed a method to separate glass without crushing and started sales of a recycling line. We have achieved the complete recycling of glass and metals.

NEDO Development Project

※ swipe to view all ←←←

| FY/Project title |

Theme |

Company/Entity |

|---|---|---|

| FY2015 -2018 Development project of PV recycling technology |

Development of complete recycling technology of glass and metals by separation method using a heated blade |

|

|

FY2014 Development project of PV recycling technology |

Development of resources recovery from end-of-life solar panels using solubilization method |

|

In 2014 and 2015 consecutively, we joined the development project of PV recycling technology of NEDO with cooperating companies and succeeded in commercialization. The result of our R&D was published in the Guidelines for Promoting PV System Recycling (2016) by the Ministry of Environment in 2016 as a reference.

Environmental Business

Solar Panel Reuse/Recycling

PV Panel Inspection Machine and Others

Solar Power Plant Inspection Service