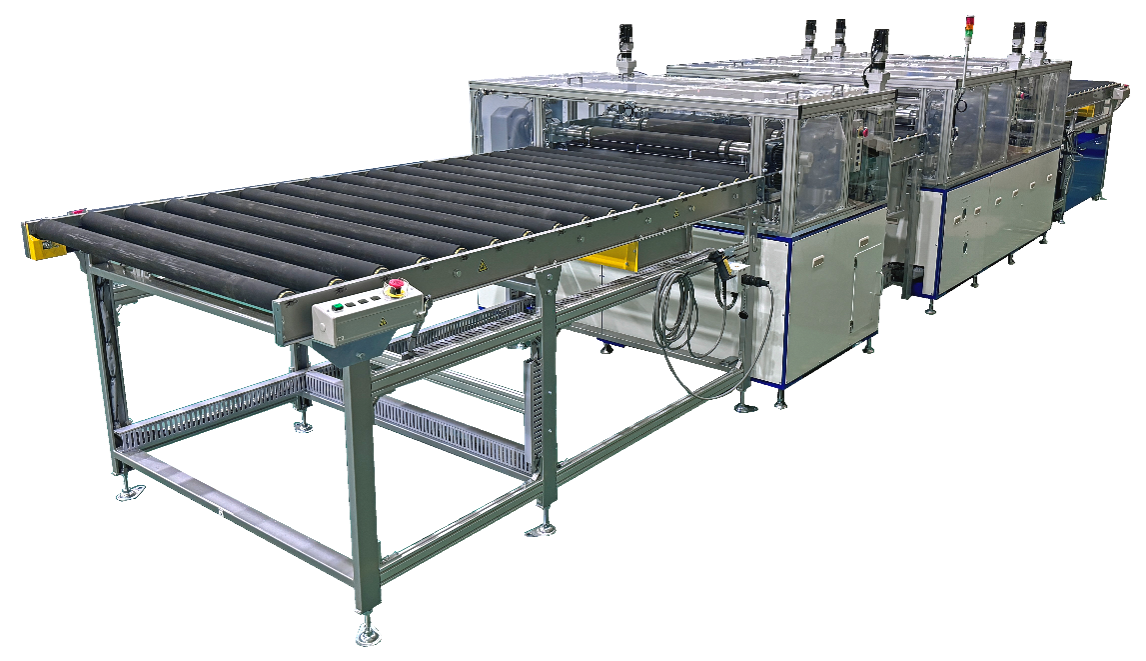

Solar Panel Recycling Machine

Make solar panel recycling more efficient and high-quality.

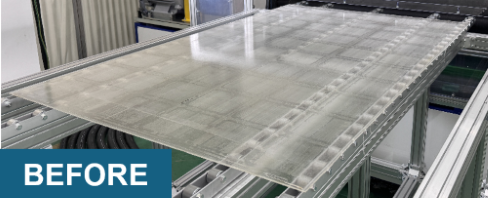

Our equipment realizes no metal residue and breakage on the glass after separation.

Lineups

Glass Separator (Hot Knife)Separates glass and cell/EVA sheet without breaking glass using our original technology, Hot Knife Separation Method.

|

| ||||

|

| Recycle | |||

Operation | |||||

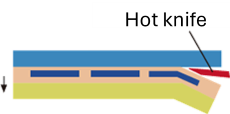

What is a Hot Knife Separation Method?

| |||||

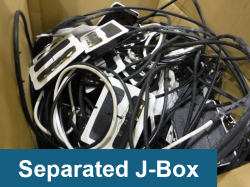

Frame & J-Box Separator(De-Framer)High-quality and cost-effective equipment ideal for initial installation.

|

| ||

|

| ||

Operation | Usable outdoorsCan be operated anywhere as long as a power source is available. Significantly reduces transportation costs by operating on site. | ||

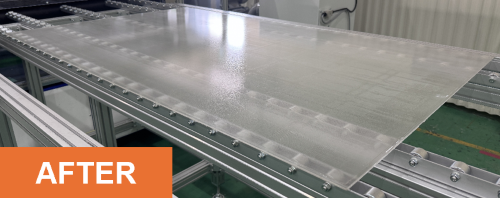

EVA ScraperRemoves residual EVA on glass surface using our original technology, Brush Scraping Method.

|

|

|

|

Operation | What is a Brush Scraping Method?

|

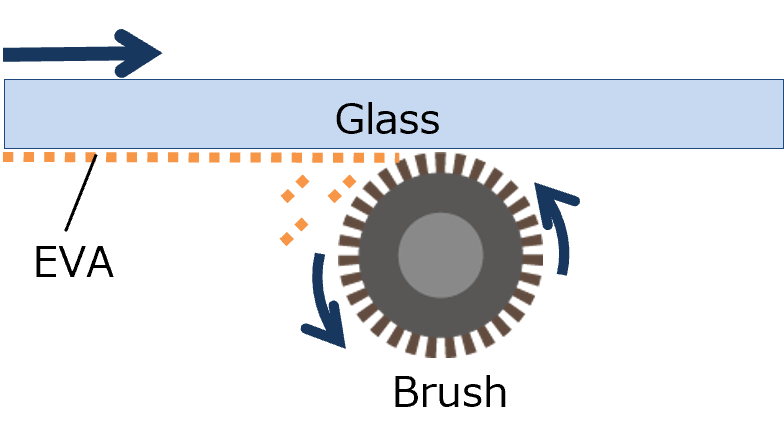

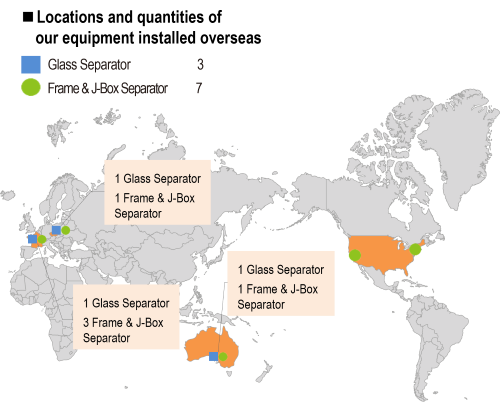

Establishing the structure for proper recycling of solar panels

|

We have been striving to establish the structure for proper recycling of solar panels. Through the structure, we will aim at creating a circular society of solar power generation.

|

|

|

|

|