太陽電池製造装置

We provide a wide range of manufacturing equipment for thin film (compound, organic, perovskite, etc.) and next-generation PV modules utilizing our 30 years of experience and expertise accumulated in providing crystalline silicon and thin film PV technology. Our equipment and lines are customized for required specifications and manufacturing processes. Inquiries from here.

|

|

Equipment for compound PV, organic PV, perovskite PV, etc.

|

※ swipe to view all ←←←

| Process | |

|---|---|

|

Bussing

Click here for information about tape pasting unit |

|

Layup

|

|

Lamination (bonding)

|

|

Post-lamination processes

|

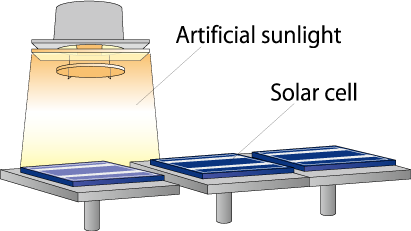

About perovskite PV

|

Perovskite PV has a wide range of applications as it is lightweight and flexible unlike conventional PV modules and can be installed where conventional PV modules cannot be installed. In Japan, where land for PV plants is limited, it has long attracted attention as a crucial technology for renewable energy expansion. R&D is in progress to overcome challenges for commercialization, such as durability. As perovskite PV has similar manufacturing processes to thin film PV, we can make the best proposal utilizing our long experience in thin film PV module manufacturing equipment. |

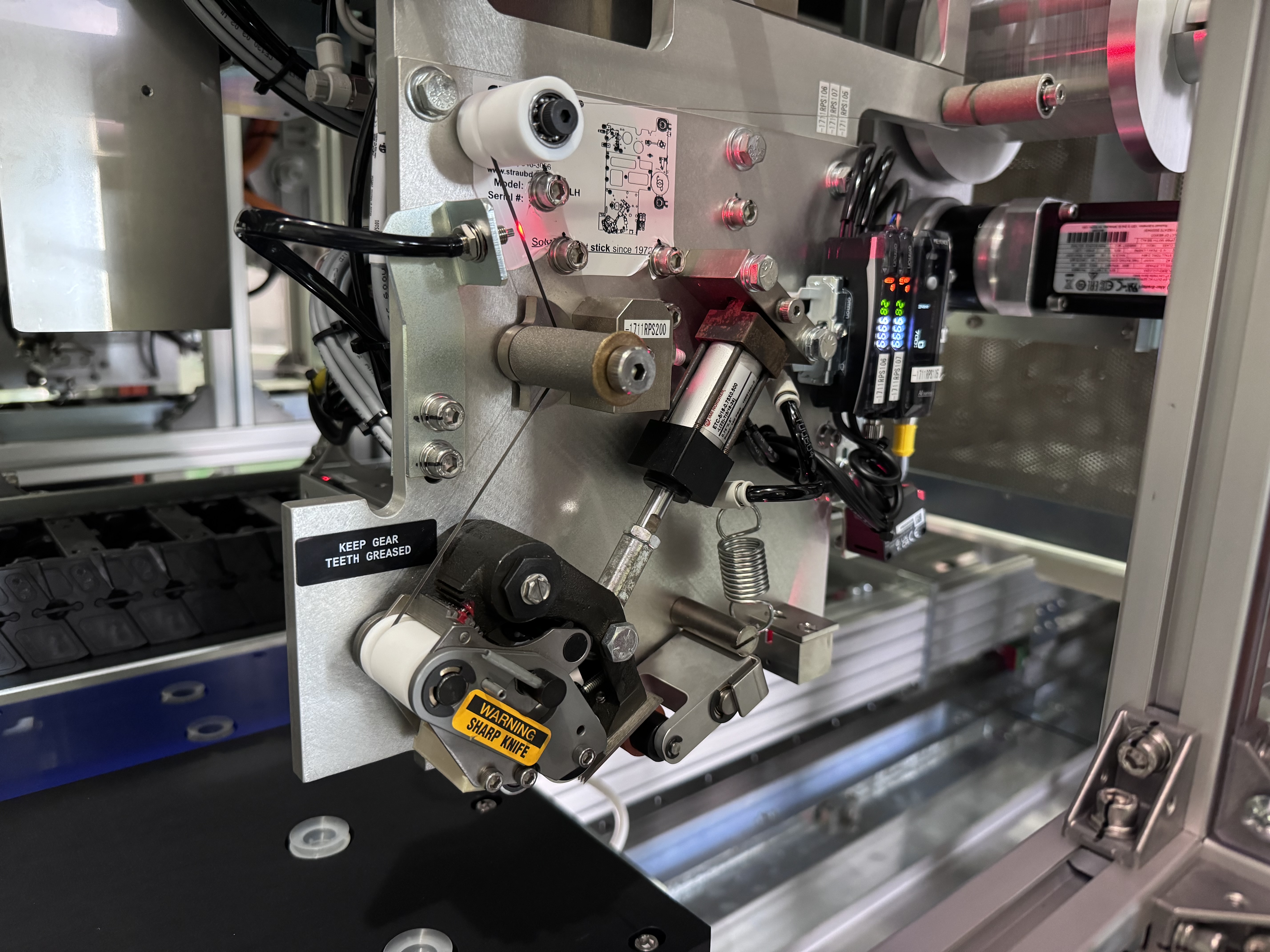

Tape Applicator Unit

|

Customizations are available according to its intended use and specifications: size (length, width, height), speed, form of supply of tape material, adding functions such as automatic collection of release paper, installation of insulation sheet, etc.

adheseve tape, double-sided tape, conductive tape, etc.

glass substrate, glass, film substrate, etc.

solar PV module (perovskite, compund thin film, etc.), bussing of smart glass etc. |

We provide manufacturing equipment of PV module for special use, such as PV for satellite, BIPV, shingled modules, etc.

|

PV modules for satellite |

Shingled PV modules |

We also offer equipment of standard PV modules for industrial and residential use.

NPC provides a wide range of equipment and engineering technologies for crystalline silicon module manufacturing. We have been continuing R&D since 1994, and have delivered optimized equipment to various customers worldwide. Utilizing our experience, we are making efforts to further develop technologies and adapt to new materials. In recent years, we have also provided equipment for manufacturing special purpose PV modules such as for satellites and shingling.

| Manufacturing Process | Solutions from NPC | |

|---|---|---|

|

Cell feeding

▼ |

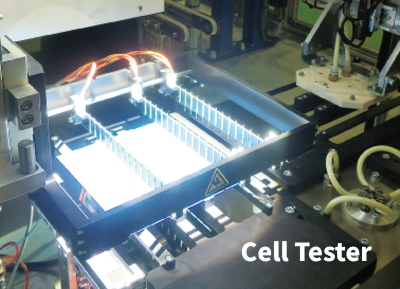

Inspect cells for chips and cracks, and categorize according to their output and physical properties.

|

・Applicable to various types of cells including highly efficient cells and back-contact cells ・Addition of laser cell cutting available |

|

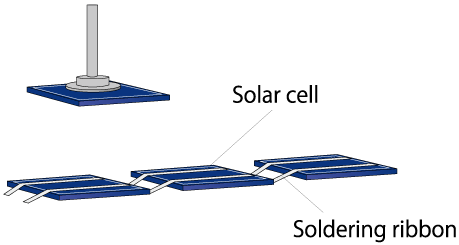

Cell soldering

▼ |

Solder cells in series to a string.

|

・Experienced in handling various wiring material ・Proposal of the best soldering method according to the material, such as hot air and IR lamp ・Applicable for cutting and shingling cells

|

|

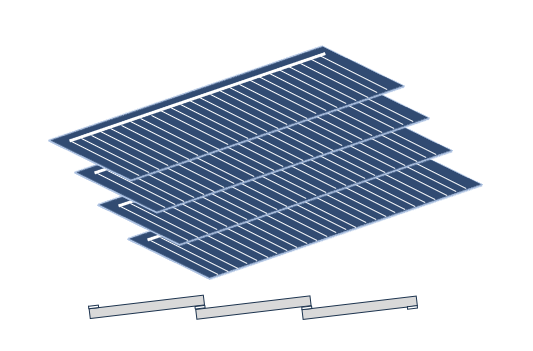

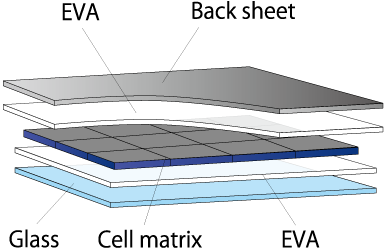

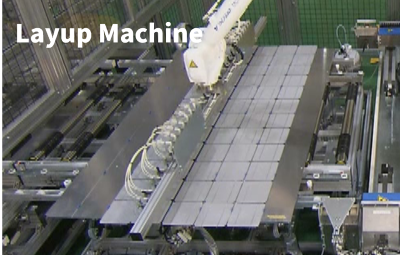

Layup

▼ |

Arrange strings in alternate direction and connect them to form a "matrix". Stack up the matrix on a glass with encapsulant and back sheet.

|

・Automated wiring material preparation

・Applicable both to roll type and sheet type

|

|

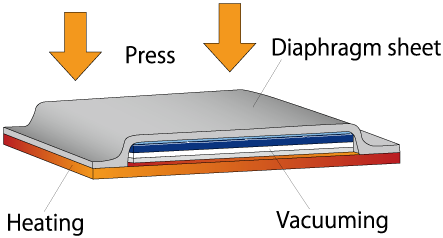

Lamination

▼ |

Laminate the materials by heating and pressing under vacuum

|

・Proposal of appropriate pressing method depending on the laminating material ・High-precision lamination for double-glass module also available

|

|

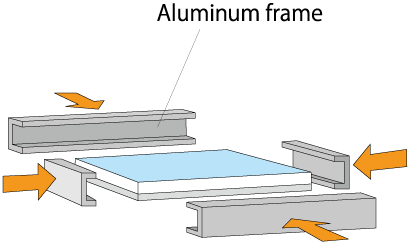

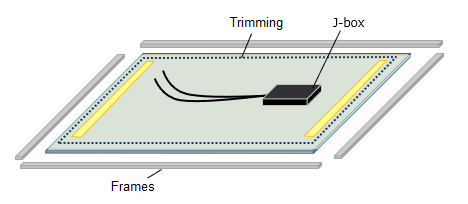

Framing J-Box attachment |

Attach aluminum frames and a junction box (J-Box).

|

|

|

Others |

Inspection of materials and modules, repairment, etc. |

|

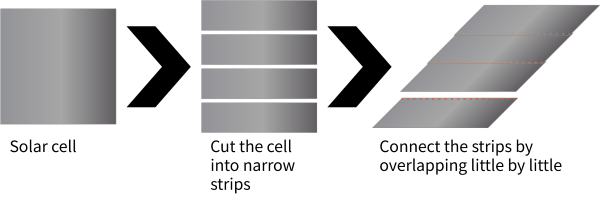

About Shingling

Shingling technology eliminates gaps between cells and the need for interconnecting ribbons so more solar cells are exposed to the sunlight and the resistive losses are reduced which make the module efficiency improve. Shingled modules are widely used in BIPV products such as residential roofs because of its beautiful appearance and higher efficiency even in a limited installation area. We offer best solutions tailored to your product specifications, from stand-alone machines to total assembly. Inquiries from here.

We offer best solutions tailored to your product specifications, from stand-alone machines to total assembly. Inquiries from here.