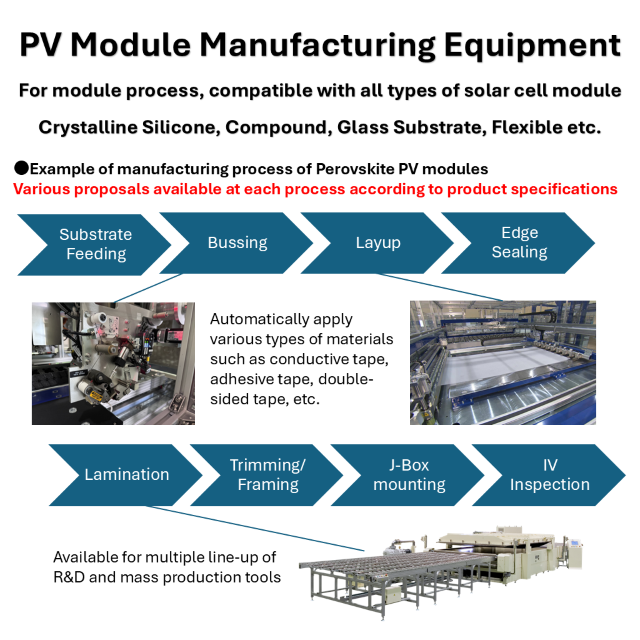

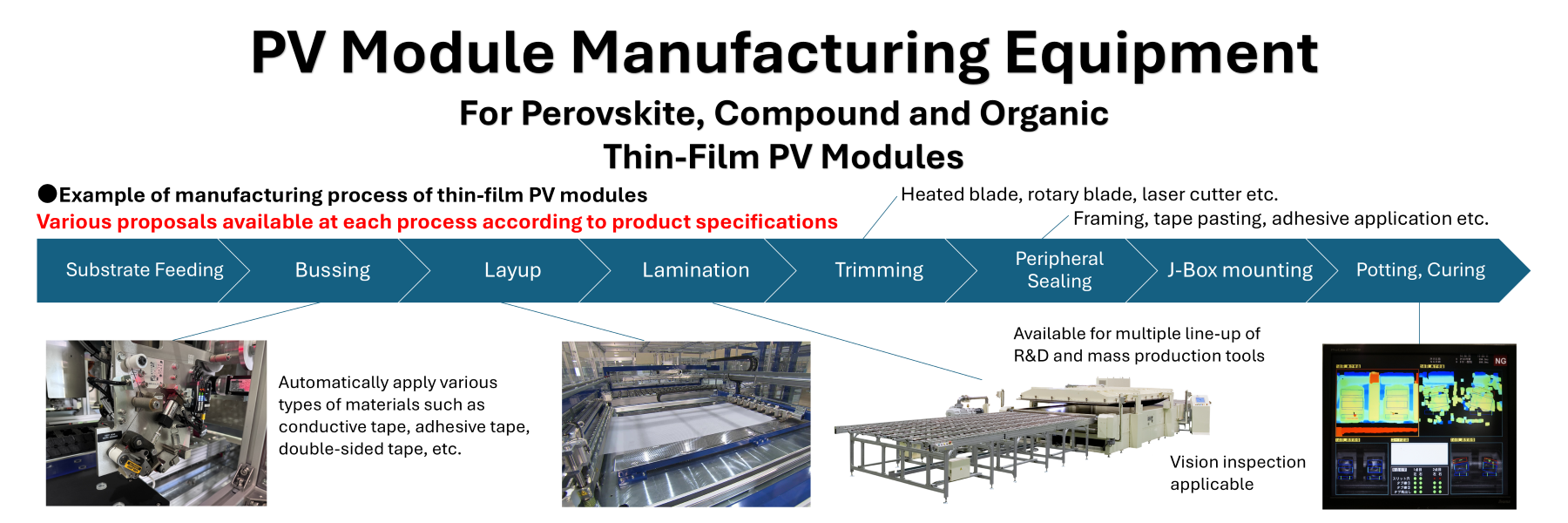

Products/Service

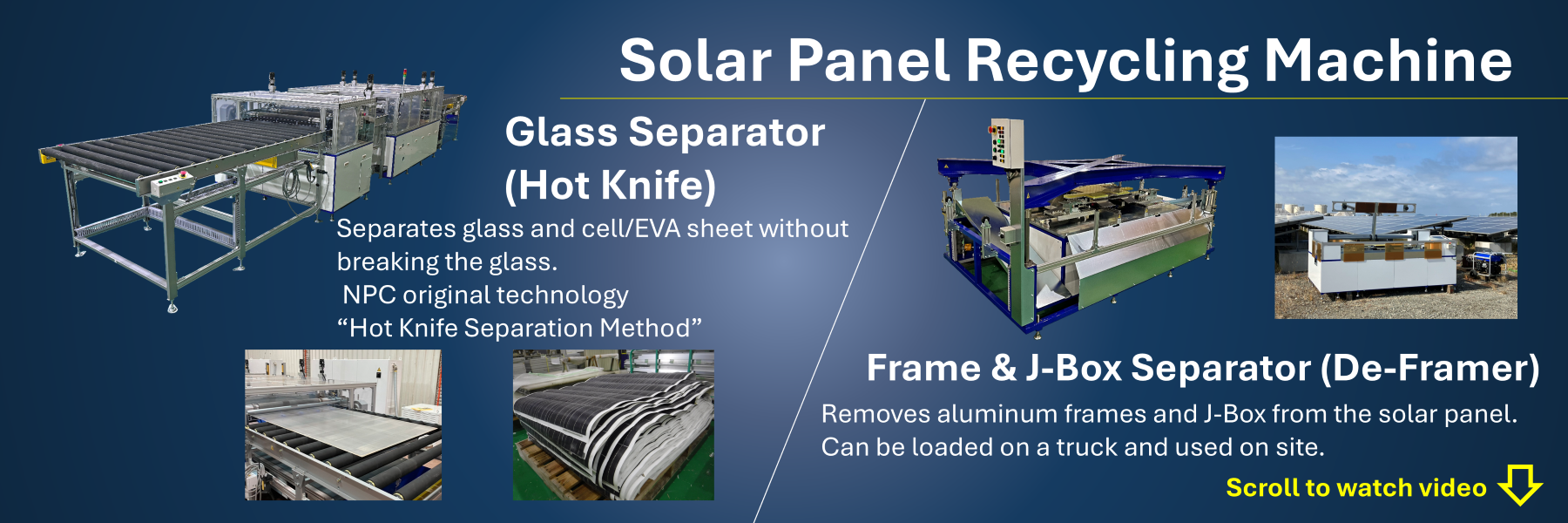

| Example of on-site operation Frame & J-box Separator for solar panel recycling | ||

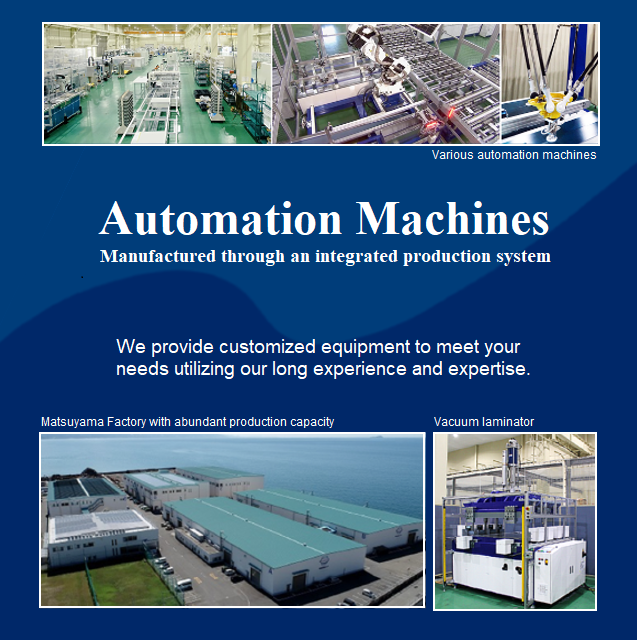

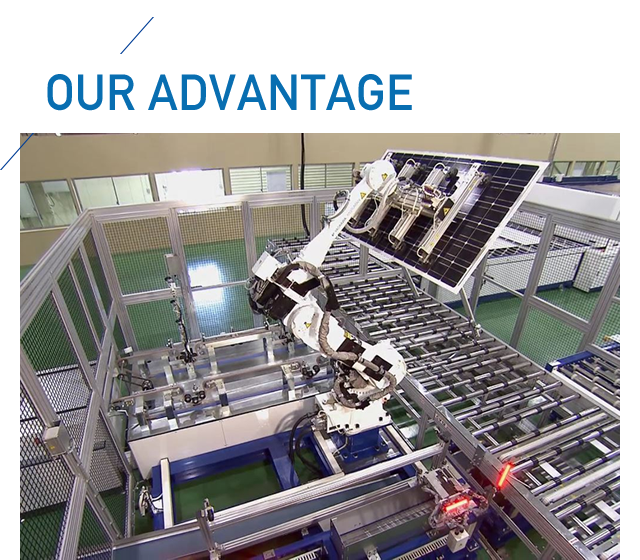

1. High technology accumulated in PV industry and ability of applying it to new industries

We have accumulated high technology in PV industry from development and sales of PV module manufacturing equipment to panel reuse/recycling. Now we provide it for a variety of industries including electronic parts,automobiles, and display.

2. One-stop service for the functions necessary for manufacturing

We are able to provide all the processes of R&D, design, procurement, manufacture, quality control, sales, and maintenance by one stop.

3. About 30 years of experiences and trust

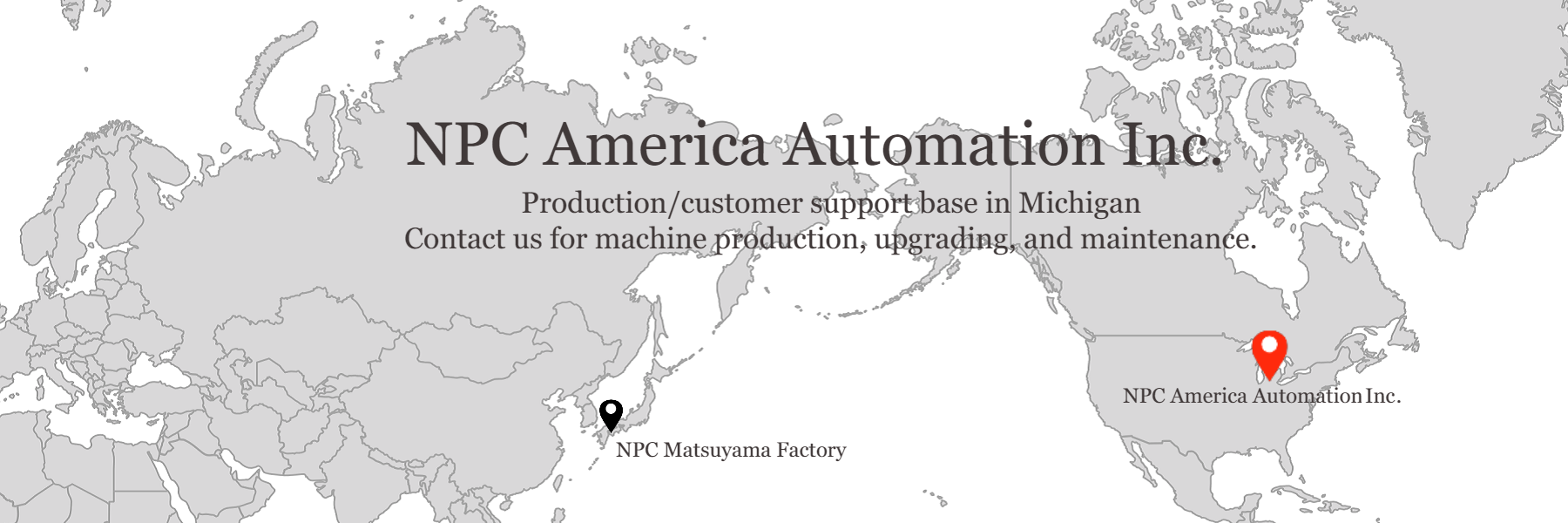

NPC entered into the PV industry in 1994, having provided PV module manufacturing equipment for about 30 years for PV manufacturers throughout the world.