PV Module Manufacturing Equipment

We provide a wide range of manufacturing equipment for thin film (compound, organic, perovskite, etc.) and next-generation PV modules utilizing our 30 years of experience and expertise accumulated in providing silicone crystalline and thin film PV technology. Our equipment and lines are customized for required specifications and manufacturing processes. Inquiries from here.

|

|

Equipment for compound PV, organic PV, perovskite PV, etc.

|

※ swipe to view all ←←←

| Process | |

|---|---|

|

Bussing

|

|

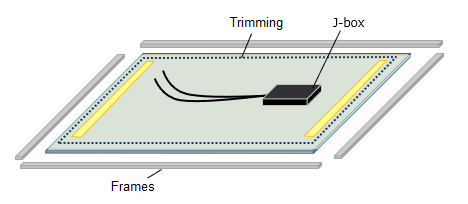

Layup

|

|

Lamination (bonding)

|

|

Post-lamination processes

|

About perovskite PV

|

Perovskite PV has a wide range of applications as it is lightweight and flexible unlike conventional PV modules and can be installed where conventional PV modules cannot be installed. In Japan, where land for PV plants is limited, it has long attracted attention as a crucial technology for renewable energy expansion. R&D is in progress to overcome challenges for commercialization, such as durability. As perovskite PV has similar manufacturing processes to thin film PV, we can make the best proposal utilizing our long experience in thin film PV module manufacturing equipment. |

We provide manufacturing equipment of PV module for special use, such as PV for satellite, BIPV, shingled modules, etc.

|

PV modules for satellite |

Shingled PV modules |

We also offer equipment of standard PV modules for industrial and residential use.

We have been developing various technologies such as adapting to new materials or advanced module structures for higher efficiency, improving throughput, and laminating technology for large modules. We propose the best equipment or assembly line according to each customer's needs. We also support customers acquiring various certificates for starting operation of module assembly lines.

Cell Tester

|

High-speed Cell Tester

Artificial sunlight |

Classifies cells according to power output measured with solar simulator.

|

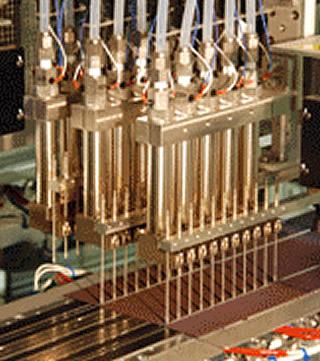

Tabbing & Stringing Machine

|

Double-head Tabbing & Stringing Machine

Soldering

Alignment inspection |

Series-connect cells by soldering wirings onto cells to form "strings"

|

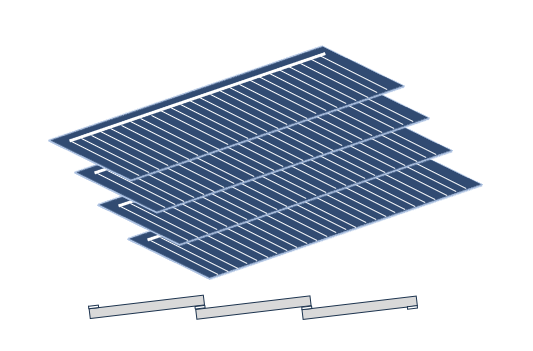

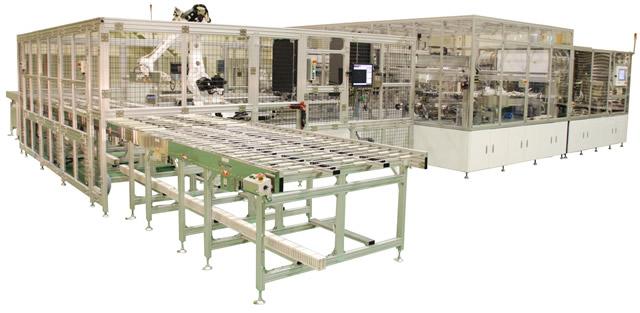

Layup Machine

|

Automated Layup Machine (multi-axis robot)

Multi-axis robot

String inspection |

Alternately supplies “strings” on stacked tempered glass and EVA

|

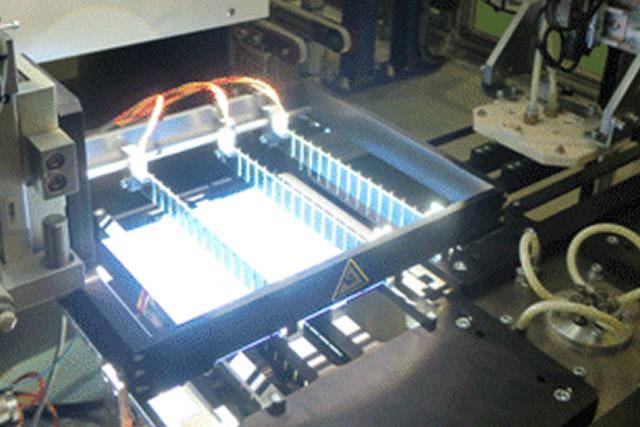

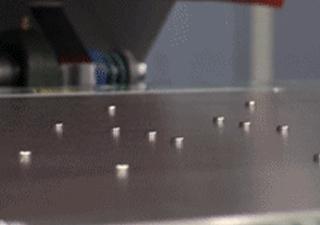

Module Laminator

|

For manufacturing line

For R&D

Supporting Device Pin |

Laminates the materials by heating and pressing under vacuum

|

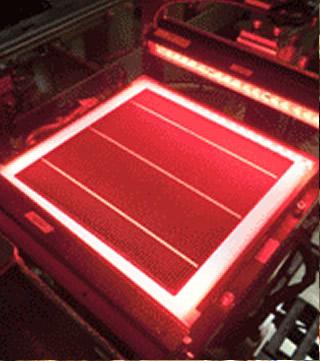

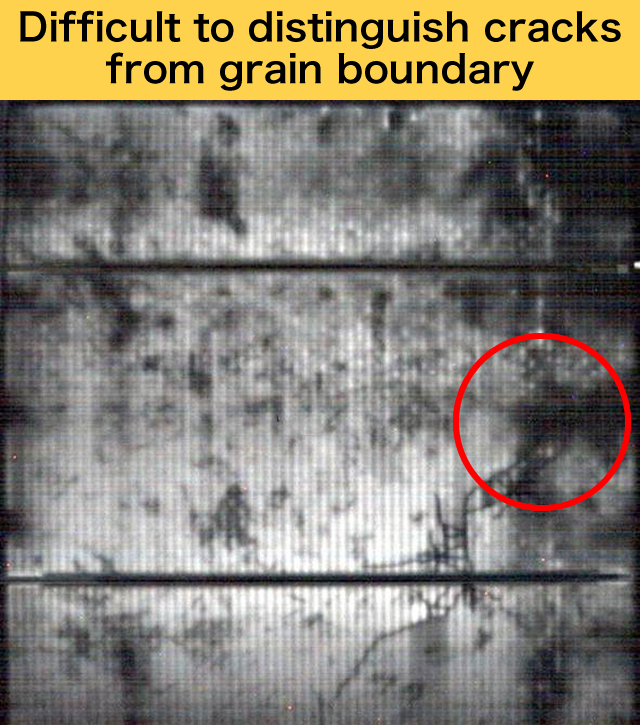

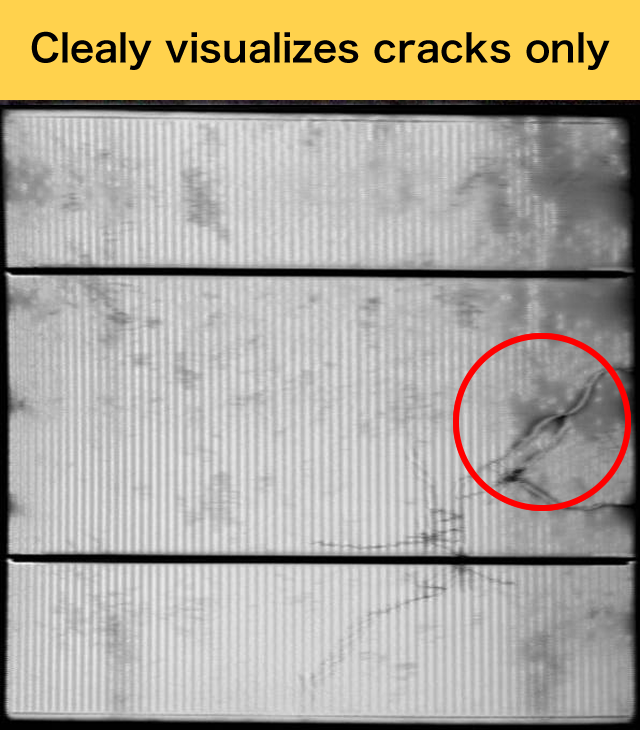

Laser Inspection Machine

|

Module Laser Inspection Machine

String Laser Inspection Machine

Cell Laser Inspection Machine

Conventional inspection method

NPC original laser inspection method |

Detects cracks in the cells/strings/modules accurately by irradiating laser beam

|

Machinery Business

-

Factory Space to Rent ( Temporarilyunavailable)